semiconductor laser diode , such as Mitusubishi ML562G85 9.0mm 638nm 2W Orange Red Laser Diode TO5 LD.

semiconductor laser system , such as 375nm Semiconductor Laser

- Light emission of semiconductor laser

A semiconductor laser (LD) is a device that causes laser oscillation by flowing an electric current to semiconductor.The mechanism of light emission is the same as a light-emitting diode (LED). Light is generated by flowing the forward current to a p-n junction. In forward bias operation, the p-type layer is connected with the positive terminal and the n-type layer is connected with the negative terminal, electrons enter from the n-type layer and holes from the p-type layer. When the two meet at the junction, an electron drops into a hole and light is emitted at the time.

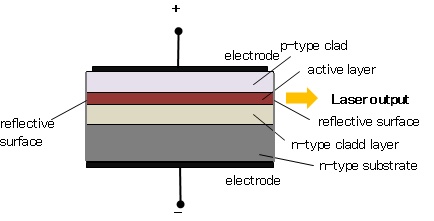

- Basic structure of semiconductor lasers

The basic structure of a semiconductor laser is shown in Figure 1. The active layer (light emission layer) sandwiched between the p- and n-type clad layers (double heterostructure) is formed on an n-type substrate, and voltage is applied across the p-n junction from the electrodes. Both edges of the active layer has mirror-like surface.When forward voltage is applied, electrons conbine with holes at the p-n junction, and emitt the light. This light is not a laser yet; it is confined within the active layer because the refractive index of the clad layers are lower than that of the active layer. In addition, both ends of the active layer act as a reflecting mirror where the light reciprocates in the active layer. Then, the light is amplified by the stimulated emission process and laser oscillation is generated.

- Types of semiconductor laser

The center wavelength of a semiconductor laser principally depends on the band gap energy of the active layer semiconductor. However, the details of laser spectra are different depending on the LD types even though the band gap energies are same.

(1) Fabry-Perot semiconductor laser

This laser has the simplest structure and is used for many applications, including optical pickups for CDs, DVDs, and BDs; laser printers; and excitation of fiber lasers. It is characterized by the use of the cleavage plane of a laser crystal for reflection of the light emitted in the active layer, as shown in Figure 1. A cleavage plane of a crystal is extremely smooth and can be used as a reflecting mirror. Since Fabry perot-LD has no mechanism to select a specific oscillation wavelength, the multiple laser oscillation occurs within the gain bandwidth as shown in Fig.2. The oscillation at multiple wavelengths causes pulse broadening in an optical fiber transmission, and therefore it cannot be applied for long-distance communications.

(2) DFB semiconductor laser

The DFB laser (Distributed Feedback Laser) has a grating below or above the active layer, and oscillates at the single wavelength defined by the Bragg wavelength of the grating. Figure 3 illustrates the structure outline. It exhibits superior performances, including a narrow spectrum width and low noise, and hence is used as an optical signal source in a long-haul optical communication.

A key product of nanoplus are complex coupled distributed feedback laser diodes. nanoplus provides these monomode semiconductor lasers at any wavelength between 760 nm and 14000 nm.

Key features of nanoplus DFB lasers

nanoplus DFB lasers have the following advantages:

stable longitudinal and transversal single mode emission

precise selection of target wavelength

narrow laser line width

mode-hop-free wavelength tunability

fast wavelength tuning

typically > 5 mW output power

small size

easy usability

high efficiency

long-term stability

(3) FBG wavelength stabilized semiconductor laser

Though DFB laser has an excellent performance like a single wavelength oscillation, it is expensive for manufacturing difficulty. More economical laser to oscillate a single wavelength is a laser diode stabilizing the wavelength by using FBG. Figure 4 illustrates the structure outline. In this case, the laser cavity is composed of the HR coated end face of the active layer and the low reflectance FBG. In figure 4, the fiber core only is drawn. The other end face of the active layer and the incident end of the fiber have AR coating to prevent reflecting light. In addition, the incidence end of the fiber is processed to a lens configuration to collect the light. Since the FBG formed in the fiber core only reflects a specific wavelength, a single wavelength oscillation occurs.

A semiconductor laser (LD) is a device that causes laser oscillation by flowing an electric current to semiconductor. The mechanism of light emission is the same as a light-emitting diode (LED). When the two meet at the junction, an electron drops into a hole and light is emitted at the time.

Semiconductor lasers or laser diodes play an important part in our everyday lives by providing cheap and compact-size lasers. They consist of complex multi-layer structures requiring nanometer scale accuracy and an elaborate design. Their theoretical description is important not only from a fundamental point of view, but also in order to generate new and improved designs. It is common to all systems that the laser is an inverted carrier density system. The carrier inversion results in an electromagnetic polarization which drives an electric field E(t). In most cases, the electric field is confined in a resonator, the properties of which are also important factors for laser performance.

Semiconductor Lasers: An Overview of Commercial Devices

Within only a few decades, the semiconductor laser diode has evolved into a family of robust, reliable devices, with individual conversion efficiencies of better than 60 percent, continuous output powers of several kilowatts, modulation rates of several tens of gigahertz, and wavelengths from 0.4 to beyond 2 µm. This article discusses the structures and characteristics of the most common commercial varieties.