Compact Narrow Linewidth External Cavity Semiconductor Laser Realized by Self-Injection Locking to Fabry-Perot Cavity

Objective Lasers with narrow linewidth and low size-weight-and-power (SWAP) are the key elements for space coherent communication, long range sensing, and quantum technology, etc. Compared with a single frequency fiber laser, a solid state laser and an external cavity diode laser (ECDL) using on-chip optical cavities and hollow Fabry-Perot (FP) cavities possess much lower thermal effects, nonlinear effects, and frequency drifts. In the past, a high performance narrow linewidth laser(NLL) realized by injection locking to a large FP cavity has been demonstrated in the laboratory, however it has never matured into a viable product due to the large FP cavity and optic bench used in the experiment. To take this technology out of laboratory and commercialize it, here we packaged and characterized a compact 1550 nm ECDL employing a miniaturized FP cavity with a high quality factor (Q).

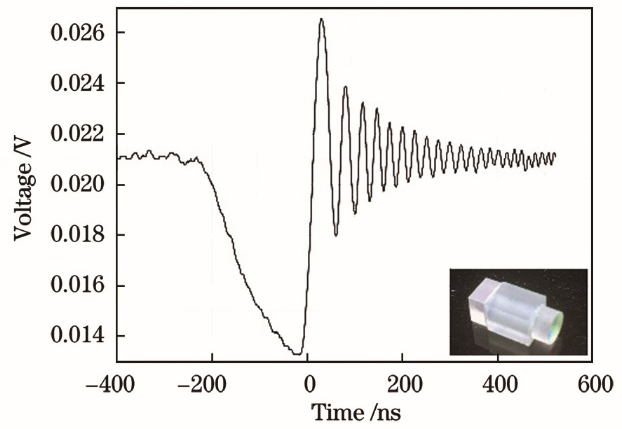

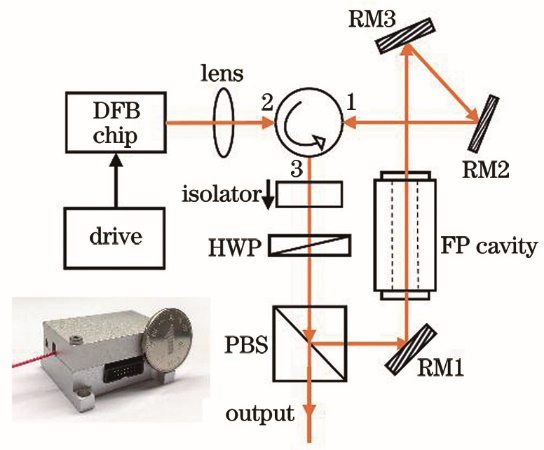

Methods We developed a miniaturized FP cavity with flat and concave mirrors with nominal reflectivity of ~99.98%. The cavity length is 7 mm and we measured its quality factor utilizing the ring-down technique and obtained Q of ~10 8(Fig. 1). We packaged an ECDL with its diagram shown in Fig.2. The light from a DFB chip was firstly collimated and sent to a circulator. The light was reflected, routed toward and coupled to the FP cavity. The transmitted light went through the circulator and was fed back to the DFB chip to form the injection locking. The DFB chip was resided on a small thermo electric cooler and the whole optical system was resided on a large thermo electric cooler. The size of the prototype was 3.8 cm×2.4 cm×2 cm. We used a home-made low noise current source to drive the DFB chip and the precise temperature controllers are used to stabilize the temperature of the DFB chip and the whole optic bench. By tuning the current, the DFB laser was injected into the selected fundamental mode of the FP cavity.

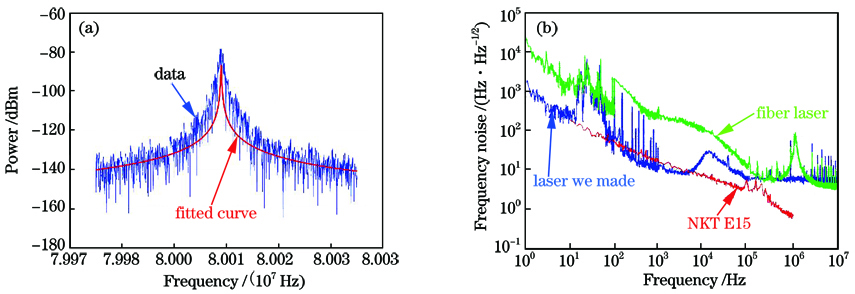

Results and Discussions We characterized the performance of the ECDL using two widely adopted methods, i.e., the self-delayed heterodyne method and the frequency discriminator method. With the first method, we used a fiber delay length of 100 km, an AOM with a frequency shift of 80 MHz and obtained the line shape shown in Fig. 3(a). The 3 dB linewidth was estimated to be ~200 Hz and the fundamental Lorentz linewidth was approximately 20 Hz based on the fitting of the baseline. With the second method, we used a commercial product and measured the frequency noise (FN), and the data was plotted in Fig. 3(b) and compared with that of a commercial fiber laser (CoSF-D). Meanwhile, the FN of the NKT E15 fiber laser was also plotted for the purpose of comparison. As was seen, the FN of our ECDL at offset frequency lower than 10 kHz was slightly lower than that of NKT E15. The noise hump at offset frequency between 10 Hz and 100 Hz was from the measurement system as it also appeared in the line of a commercial fiber laser (CosF-D). Finally, we measured the temperature-frequency tuning sensitivity of our ECDL to be around 200 MHz/K, which was much lower than those of materials used in a fiber laser, a solid state laser and an on-chip ECDL.

Conclusions We have shown an ECDL based on injection locking of DFB chip to a compact high Q FP cavity, and it is a viable way to obtain a high performance NLL with low SWAP and low cost. This first prototype we have packaged has shown frequency noise comparable to that of the well-known NKT E15 fiber laser at offset frequency of <10 kHz. By improving the Q of the FP cavity and implementing an advanced packaging technique, we believe its performance can surpass that of the NKT X15 fiber laser.